The Ultimate Purchaser's Overview to OEM Construction Parts

Exploring the Perks of OEM Construction Components in Ensuring Seamless Procedures on duty Site

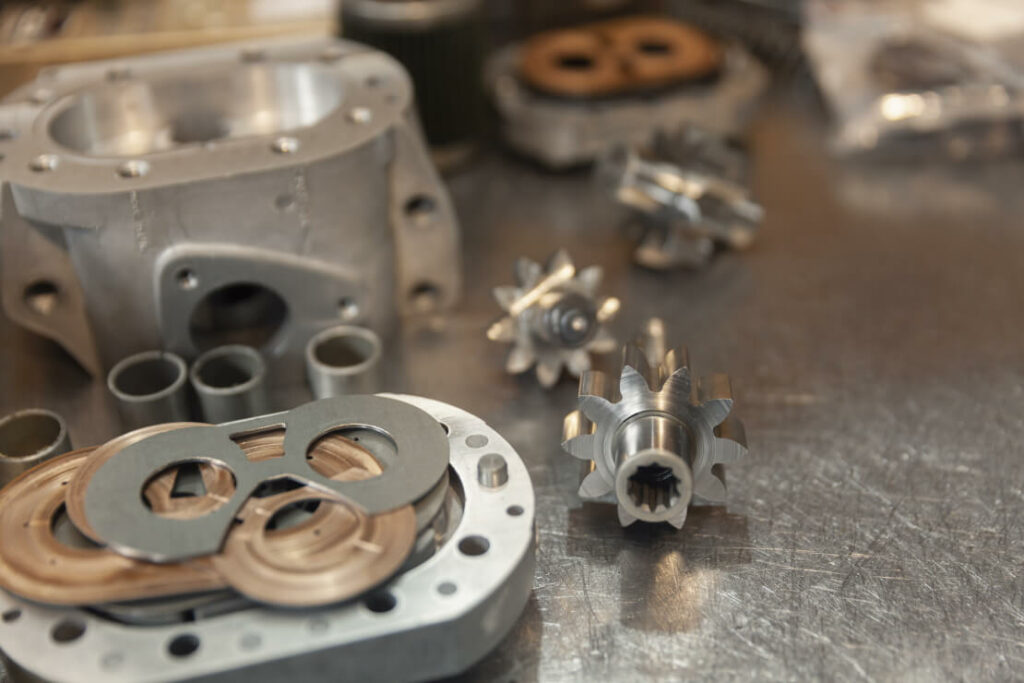

In the world of construction operations, the reliance on Original Tools Manufacturer (OEM) construction parts plays an essential duty in keeping the efficiency and capability of hefty equipment and tools on job sites. These elements are designed to satisfy the precise requirements and criteria set by the equipment makers, making certain optimal performance and compatibility. As the backbone of smooth operations, the utilization of OEM construction parts provides a variety of advantages that go beyond mere capability. From strengthening tools efficiency to enhancing precaution and extending the life expectancy of machinery, the advantages are manifold. It is essential to check out in depth exactly how these OEM components add to seamless procedures and why they remain a foundation of success in the construction market.

Enhanced Tools Efficiency

Improved tools efficiency is an essential aspect that highlights the value of making use of OEM construction parts. Original Devices Manufacturer (OEM) parts are particularly developed to fulfill the precise requirements of the devices, making sure optimum performance and longevity. When construction business use OEM parts in their machinery, they can substantially enhance the efficiency and efficiency of their devices on the work website.

One key advantage of OEM building components is their compatibility with the devices they are planned for. OEM components are engineered to seamlessly incorporate with the machinery, minimizing the danger of malfunctions or breakdowns that can accompany common or aftermarket parts (Oem Construction Parts). This compatibility translates into better tools performance, as OEM components preserve the intended performance and quality of the equipment

In addition, OEM building and construction components undergo strenuous testing and quality assurance actions to satisfy sector criteria. This interest to information guarantees that the parts are resilient, trusted, and qualified of standing up to the requiring conditions of construction work. By making use of OEM building components, business can maximize the efficiency of their tools, leading to enhanced productivity and cost savings in the future.

Lessened Downtime

By utilizing OEM building and construction components, construction business can substantially lower downtime, therefore improving general functional effectiveness. Downtime on a building and construction website can be pricey, creating hold-ups in project timelines and boosting labor prices. OEM construction parts are created to fit seamlessly with the original equipment, guaranteeing optimal performance and lowering the danger of break downs.

When utilizing OEM parts, construction companies can decrease the moment needed for upkeep and repair services. OEM parts are constructed to precise requirements, ensuring an ideal fit and trustworthy functionality. This minimizes the opportunities of unanticipated equipment failings that can lead to unintended downtime.

In addition, OEM components are known for their high quality and resilience, giving longer-lasting services compared to aftermarket alternatives. By purchasing OEM construction parts, companies can avoid regular replacements and repairs, ultimately conserving money and time over time.

Improved Precaution

Carrying out OEM construction parts can lead to a significant improvement in security actions on building and construction websites. OEM components are particularly created to fit and operate appropriately within the machinery they are meant for, making sure optimum performance and minimizing the threat of malfunctions that might jeopardize safety and security. By utilizing OEM parts, building firms can maintain the honesty of their equipment, reducing the possibilities of failures or crashes due to incompatible or malfunctioning elements.

In addition, OEM parts undertake extensive testing and quality assurance procedures to satisfy industry requirements and specs. This commitment to quality and reliability translates straight into enhanced safety on duty site. Workers can believe in the devices they are using, recognizing that it is outfitted with genuine OEM components that have been confirmed to carry out safely and efficiently.

Along with lowering the probability of equipment-related accidents, OEM components likewise add to a more secure job environment by promoting correct functioning of equipment and adherence to safety and security methods. In general, spending in OEM building and construction components is an aggressive step towards improving safety procedures and guaranteeing the health of employees in the building and construction market.

Extended Devices Life-span

Making use of OEM building parts can dramatically extend the operational life expectancy of devices on construction sites. go to my blog Initial Equipment Producer (OEM) parts are crafted to accurate specs, ensuring compatibility and optimal efficiency within the equipment they are made for. By using OEM building and construction parts, building and construction companies can preserve the stability and functionality of their machinery, bring about extended equipment life expectancy.

One trick benefit of OEM building components is their high quality and reliability. These parts are produced to meet the very same criteria as the initial elements, ensuring a proper fit and efficiency. This precision in style and building and construction decreases the risk of early deterioration on the equipment, ultimately enhancing its longevity.

Additionally, OEM parts typically feature service warranties, providing added guarantee to building and construction companies pertaining to the longevity and efficiency of the elements. This guarantee protection can provide tranquility of mind and monetary defense in instance of any type of unexpected issues, additionally supporting the prolonged life-span of the devices. By spending in OEM construction parts, construction firms can make certain that their equipment operates efficiently for an extended period, optimizing performance and lessening downtime.

Streamlined Upkeep Procedures

Having actually developed the benefits of OEM building parts in lengthening the functional life-span of devices, a concentrate on structured maintenance procedures becomes critical for making sure continued effectiveness and dependability on construction websites. Structured maintenance processes describe the systematic technique required to maintenance machinery and devices with accuracy and moved here timeliness. By adhering to a well-structured maintenance schedule that includes regular evaluations, cleansing, lubrication, and minor fixings utilizing OEM parts, construction business can decrease downtime and avoid expensive break downs.

Executing a proactive upkeep technique not just boosts the overall efficiency of the equipment yet additionally adds to a much safer working setting for building and construction workers. Ultimately, prioritizing structured maintenance processes with OEM construction parts is important for taking full advantage of efficiency and guaranteeing smooth procedures on the task site.

Verdict

In the realm of construction operations, the dependence on Original Tools Supplier (OEM) building parts plays a critical function in keeping the effectiveness and performance of hefty equipment and equipment on task websites.Applying OEM building parts can lead to a significant enhancement in security procedures on building and construction sites.Making use of OEM construction parts can significantly prolong the functional life-span of devices on building sites. By using OEM construction parts, building and construction companies can keep the stability and capability of their equipment, leading to prolonged devices life expectancy.

Having established the advantages of OEM building and construction parts in lengthening the operational life-span of devices, a focus on structured upkeep procedures becomes critical for guaranteeing ongoing performance and reliability on construction websites.